Products

ArkMix AB IS READY TO SERVE YOU

The company offer essential services in agitation used by companies in the process industry. With traditions dating back to 1946, the company specialise in serving you.

As a result of the constantly increasing demand for agitator solutions the company has developed a calculation method to size agitators both process wise and for the mechanical parts. The company’s main activities comprise the development, design, production and marketing of agitators.

The company find its application in the chemical plants, public utilities, the pulp and paper industry as well as in the mining, pharmaceutical and food industries.

The demand for reliable agitators is rapidly increasing in the environmental engineering sector, in particular in wastewater and biological waste plants. The challenge of environmental protection has become a global issue of enhanced importance.

Our quality of service and ability to promote agitator projects within all industry branches put us in the forefront as agitator specialists. As the company has strengthened its position on the market it is to be seen as a further challenge with ambitious expanding plans.

The agitators have been manufactured in accordance with the state of the art and are delivered in a condition that allows safe and reliable use. Any changes made by the user which affect safety and reliability are prohibited.

ArkMixAB agitators are approved according to EU-directives for CE-mark and ATEX for hazardous location according to ATEX directive 2014/34/EU

Data needed for dimensioning of agitators

- Explain under which circumstances the agitator shall perform

- The purpose of the agitation

- The working volume and variation in max / min levels

- Measurements of the tank and location of the liquid level

- Position of the inlet

- Position of the outlet

- Viscosity and/or dry solid content

- Density

- Temperature

- Retention time

- Pressure

Through the values given ArkMIx calculates with their own developed method the proper degree of agitation by choosing the right number of impellers and placing them in the right position. By turning the impellers with a sufficient speed of revolution, the liquid will move in accordance with the purpose of the agitation.

ArkMix makes it stronger

Our prime target is to deliver appropriate mixers with both process- and mechanical warranty. We will always calculate a secure agitation process with warranty – that’s our core task.

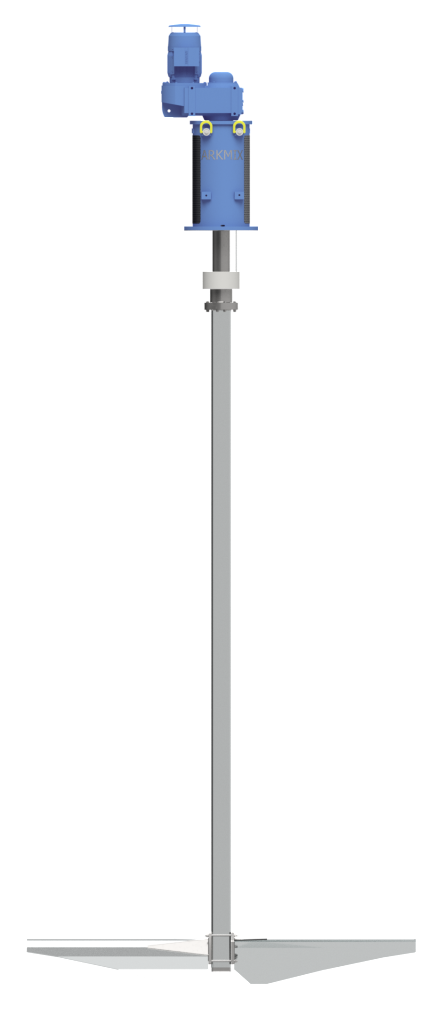

When it comes to mechanical solutions we are able to offer two versions. One main stream version (me to) and our supreme alternative the modular built ArkMix agitator solution. The modular build-up parts are dimensioned to stand fare higher forces – leading to Maximum uptime, very low Life Cycle Cost and peace of mind for the Operator.

The Orgalime S 2012 General Conditions which we use says; “The Supplier’s liability shall be limited to defects which appear within a period of one year from delivery”

For the ArkMix modular built agitator’s we´ll extend the warranty to 2 years from delivery.

4HFI

2HFI

2HFI on shaft

Installation / Commissioning

The counter flange on the tank must be very clean, even, and free of burrs. The flange inclination from the horizontal is maximum 1 mm / 1000 mm.

During commissioning it is recommended to keep an eye on the machine for a period of time and ensure that everything is going well.

ArkMix is able to send an installation supervisor to site for installation and commissioning. It is better for the customer to have at least an installation go-ahead from ArkMix prior to the installation.

ArkMix can also supply the needed baffle plates which are to break the turn of the liquid, to avoid the shaft turning with a potential vortex, and to create a controlled liquid flow from top to bottom inside the tank. Ladders, stairs, platforms and railings are also parts we are able to supply.

Monitor & Control Exypnos

The ultimate monitoring and control for agitators

General

- Unique agitator process configurable; biogas, waste water, water treatment, chemical process plants, etc.

- Up to six agitators managed by one Monitor & Control Exypnos control unit

- Monitoring, Control and Parameter configuration using the touch screen

- Offers the same touch screen contents and control for several external computers simultaneously

- Language selection on the touch screen